up ko ani karong morning..

Results 71 to 80 of 850

Thread: All about woodworking

-

06-21-2010, 05:44 AM #71

-

06-21-2010, 10:32 AM #72

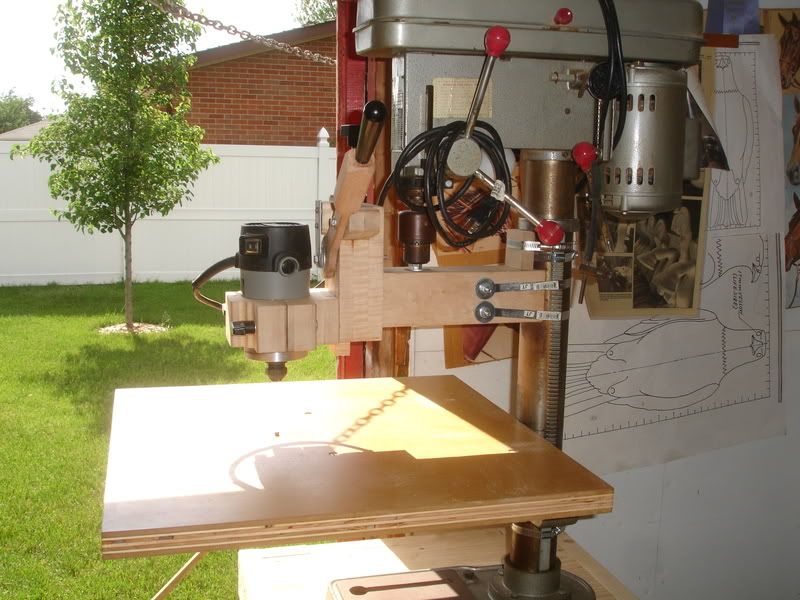

Add Ons to your Stationary Tools.

-

06-22-2010, 12:07 PM #73

up ko ani..

-

06-23-2010, 09:42 AM #74

Test your gluing knowledge

Answer these true-or-false questions to see what you know about adhesives and gluing.

1. All glues are the same; they all work on wood. - TRUE or FALSE

2. There is not one great glue that will do it all. -TRUE or FALSE

3. All white/yellow glues are the same. - TRUE or FALSE

4. Yellow glue is strong-White glue is only used by schoolchildren. - TRUE or FALSE

5. There is no glue like the old hide glue. - TRUE or FALSE

6. Aliphatic glue is superior. - TRUE or FALSE

7. Formaldehyde glues are waterbased. - TRUE or FALSE

8. Water based glues are harmful because they will swell and twist wood. - TRUE orFALSE

9. Thick glue is better and fills gaps and voids. - TRUE or FALSE

10. More glue is better. - TRUE or FALSE

11. More pressure is better. - TRUE or FALSE

12. More catalyst is better. - TRUE or FALSE

13. No glues will take a stain. - TRUE or FALSE

14. Mechanical help such as biscuits or dowels is needed for best edge gluing strength. -TRUE or FALSE

15. Miters and other end grain can be glued with any thick glue. - TRUE or FALSE

16. Moisture content is important; gluing air dried lumber is not a good idea. - TRUE orFALSE

17. Pieces should be assembled as soon as possible after spreading the glue. - TRUEor FALSE

18. There are glues that will set in 3-5 minutes allowing very fast edge gluing of hardwoods. - TRUE or FALSE

19. It's OK to machine immediately from press/clamps. - TRUE or FALSE

20. Heating the glue line will not speed the cure. - TRUE or FALSE

21. "Water Resistant" on the label means the glue isn't affected by water. - TRUE orFALSE

22. Glues with toxic chemicals in them shouldn't be used. - TRUE or FALSE

23. Water based glues can be used as long as the temperature in the shop is above freezing. - TRUE or FALSE

24. Shops don't need to be humidified in the winter. - TRUE or FALSE

25. It's OK to glue bowed, bellied or twisted stock as long as it's pulled tight with clamps.- TRUE or FALSE

26. Glue performance can be easily tested in the shop. - TRUE or FALSE

27. Powdered glues that require water for mixing are more likely to bleed through veneers than PVAs. - TRUE or FALSE

28. Glues last forever; there is no shelf life. - TRUE or FALSE

Answers:

Spoiler!

-

06-24-2010, 08:24 PM #75

up ko ani for today..

-

06-25-2010, 09:12 AM #76

up for this day.. ask pa mo

-

06-26-2010, 07:27 PM #77

-

06-26-2010, 07:33 PM #78

-

06-27-2010, 02:26 PM #79

-

06-27-2010, 06:41 PM #80

usna man nga wood kuno?

Advertisement

Similar Threads |

|

Reply With Quote

Reply With Quote